Is Reverse Osmosis System is good for the environment?

Reverse osmosis is one of the greenest solutions for industrial wastewater. Another environmental benefit of RO is the capture and correct disposal of impurities within the mains water feed. This is without the discharge of harmful chemically saturated water going to effluent or drain.

Industrial wastewater is a major culprit of water pollution. This is because companies are disposing of wastewater incorrectly without treating or managing it first. Reverse osmosis purifies the wastewater before it goes to drain, making for a green water solution that meets water regulations.

RO uses no chemicals to treat wastewater, just cleverly designed membranes. Help Save Nature advises that large-scale industries operate their own on-site treatment systems to reduce the amount of pollutants, such as RO.

Why Industrial RO is good for the environment?

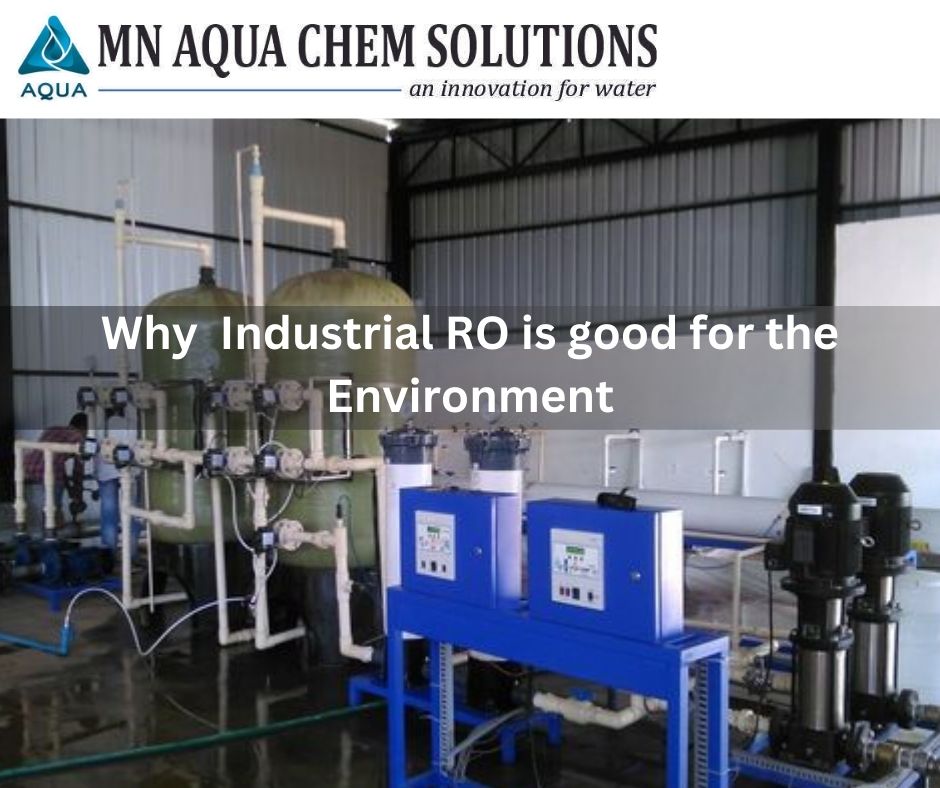

Reverse osmosis is a modern solution to wastewater treatment. The cutting edge spiral design of membranes remove the impurities from the water feed without the use of chemicals, resins, or ion exchange beds.

Wastewater produced from manufacturing can be contaminated with damaging products. For instance the wastewater created from producing a car can include metals, oils, grease and harmful chemicals from paint residue.

If this wastewater was to re-enter the water cycle without the correct treatment it could cause long-term damage to the environment.

Reverse osmosis removes certain impurities allowing you to reuse the water in the production process or release the water to drain without causing any harm to the environment.

Water pollution is also harming animals, killing fish that then have a knock-on effect on the food pyramid as a whole.

As the industrial sector contributes heavily to the quantity of harmful wastewater that re-enters the water cycle, it’s their corporate social responsibility to prevent it.

Society is becoming more eco-conscious, with companies using this to their advantage by generating green campaigns and improving the way they manufacture products.

Poor water treatment management can incur high fines and serious punishments such as imprisonment of the managing director of the business that fails to meet regulations.

RO systems are self-cleaning, self-contained units that look after themselves. They are powered by electricity and only require a daily check from onsite personnel.

How is reverse osmosis used in the industrial process?

Reverse Osmosis is very effective in treating brackish, surface and ground water for both large and small flows applications. Some examples of industries that use RO water include pharmaceutical, boiler feed water, food and beverage, metal finishing and semiconductor manufacturing to name a few.

An RO system can be installed in the production line of any manufacturing process that requires precise water. As raw water enters the system from either a break tank or mains feed, high-pressure pumps drive the water through a set of membranes.

These membranes are selective barriers that capture impurities such as salts, or solids. Each RO system is installed with specific membranes to remove the relevant impurities, these are dependent on the quality of water at your location.

The water leaves the RO system as clean water, ready to be used in production. Used frequently in pharmaceutical pure water systems due to its capability of rejecting 99.9% of bacteria.

Conclusion

It is more environmentally friendly to use RO as an industrial wastewater solution as opposed to employing dangerous chemicals. In order to securely re-enter the water cycle or even be reused in manufacturing, pressure and specially constructed membrane systems eliminate hazardous pollutants.

One of the main advantages of RO is the significant environmental impact it has. Laws and regulations are anticipated to tighten as society becomes more aware of issues like water contamination.